The small silo for bagged goods, big bags and one-way containers with an integrated 400 V continuous mixer und 400 V delivery pump

Benefits at a glance

- Can be used for all pumpable, powdery ready-mixed mortar

- Powerful 400 V machine technology

- Very high delivery rate

- Continuously variable speed control

- Simple to operate

- Easy-to-clean thanks to PU mixing pipe

- Filling with bagged goods is standard. The small silo can also be filled with big bags or one-way containers

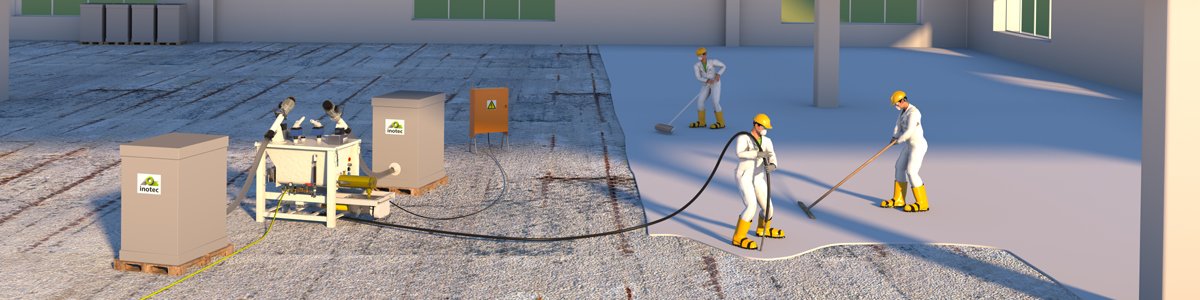

The inoCOMB Cabrio small silo is the ideal solution for anywhere that a lot of material has to be processed in a short amount of time. On the construction site, machine technology is used to ensure the smooth operation of the high-performance 400 V continuous mixer and the tried-and-tested delivery pump. With the optional sets that are available, the small silo can be converted for various fields of application in just a couple of steps. This offers maximum flexibility on your construction site thanks to unlimited areas of application (e.g. spraying, bonding, moulding of floor levelling compounds, filling and reinforcing)

The small silo can be filled with bagged goods, big bags via an optional attachment hood or with one-way containers.

Video

Alternative Machines

Service details

| Operating voltage | V/Hz/A | 400 / 50 / 32 |

| Drive performance | kW | 6,3 (frequency controlled) |

| Empty weight | kg | 420 |

| Delivery rate (depending on the material) | l/min | max. bis ca. 100 |

| Conveying distance (depending on the material) | m | max. 80 |

| Pressure height (depending on the material) | m | max. 40 |

| Material container | l | 200 |

| Water connection | bar | 4 (¾") |

| Machine technique | Silo and machine technology | |

| Comments | * Motorleistung Continuous mixer: 4,0 kW / Delivery pump 6,3 kW | |

| Dimensions (L x W x H) | mm | 1200 x 800 x 1300 |

| Weight | kg | approx. 420 |

inoCOMB Cabrio | |

| Bonding or reinforcing mortar | |

| Can be used for all pumpable, powdery screed and levelling compounds | |

| Concrete smoothing compound | |

| Facade plasters | |

| Floor leveling compound | |

| Grouting of channels and machine foundations | |

| Organic spattling compounds | |

| Reprofiling mortar | |

| Spraying final coats |

Scope of delivery

inoCOMB Cabrio

Item no. 10042272 (NEW)

Item no. 10042612 (refurbished)

Small silo consisting of:

- Frame

- Material hopper

- Switching cabinet

- Vibrating unit

Mixing unit consisting of:

- Gear motor

- Water fitting

- inoPOWERMIX “S” PU mixing pipe with wide material outlet

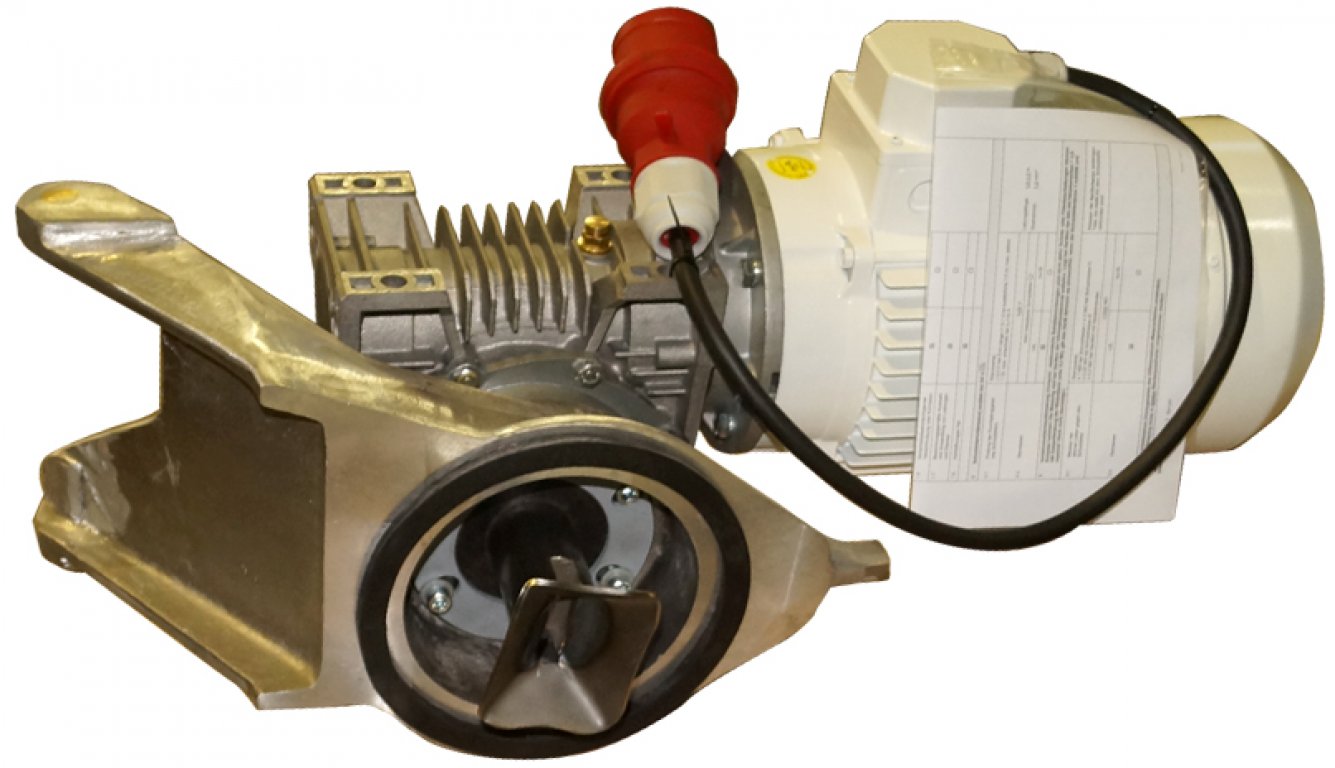

Pump unit consisting of:

- Detachable delivery pump,

- Pump housing made from stainless steel

- Gear motor frequency-controlled

- Tool set

Set “D”-Cabrio

for spray applications (22 l / 40 bar)

Item no. 10043990*

Set “Ü1”-Cabrio

for industrial screeds (100 l / 15 bar)

Item no. 10043988*

Set “Ü2”-Cabrio

for floor levelling compounds (100 l / 30 bar)

Item no. 10043989*

Set “RS”-Cabrio

for coarse-particle materials (50 l / 15 bar)

Item no. 10043991*

------------------------------------------------------------

* For delivery contents, see accessories

First aid set for Cabrio small silo

Scope of delivery:

Systainer, grease guns incl. 2 cartridges, ratchet combination wrench 24 mm switchable, combination wrenches SW24 and SW13, Geka coupling 3/4” nozzle and 3/4” IT and 1” IT, Geka spray nozzle 3/4”, Geka coupling 1/2” nozzle, Geka sealing system with beaded edging, sieve insert made from brass, replacement sieve for pressure reducing valve D06F, sealing system for coupling 35 / 42 / 50 mm, cleaning piece 50 M part and 35 M part with Geka coupling, sponge ball 45 mm RG250 and 60 mm RG200, corner pipe wrench 3”, multifunctional putty B75 mm, stainless steel, special assembly lubricant spray (400 ml tin), connecting coupling for compressor (Geka/claw coupling), bench hammer 300 g, hose clamp 1/2” and 3/4” clamping range, Stanley FatMax tool box.

Set “RS”-Cabrio (rotor/stator R7-1.5 with clamping strip)

- Ø 115 mm, 50 l/min, 15 bar, e.g., for coarse-grained material such as grouting concrete

Scope of delivery:

Suction flange, pressure flange, mortar pressure gauge, rotor/stator R7-1.5 with clamping strip, coupling M part 50 (2” IG)

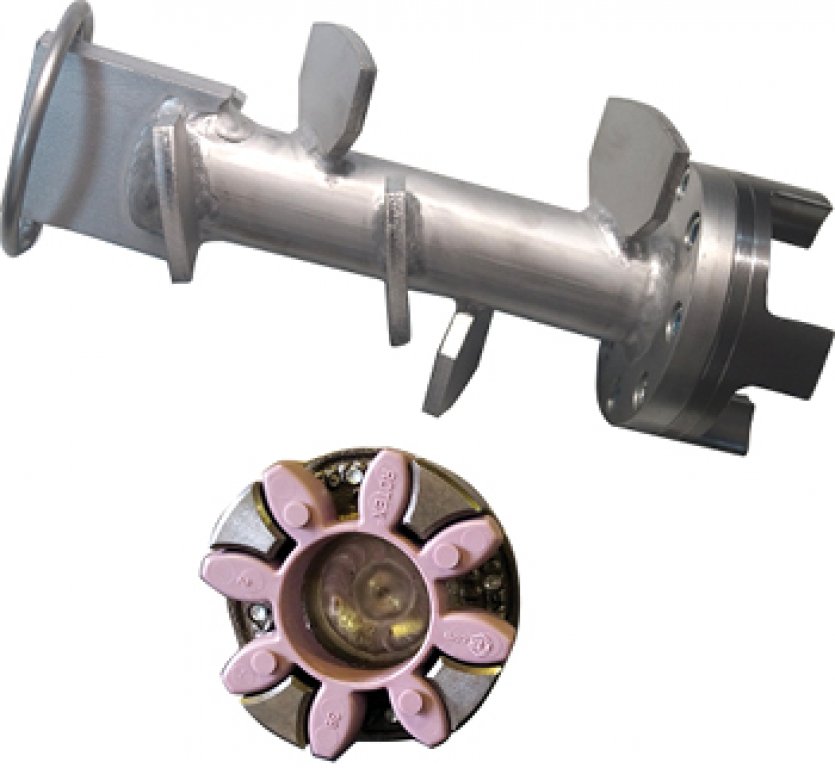

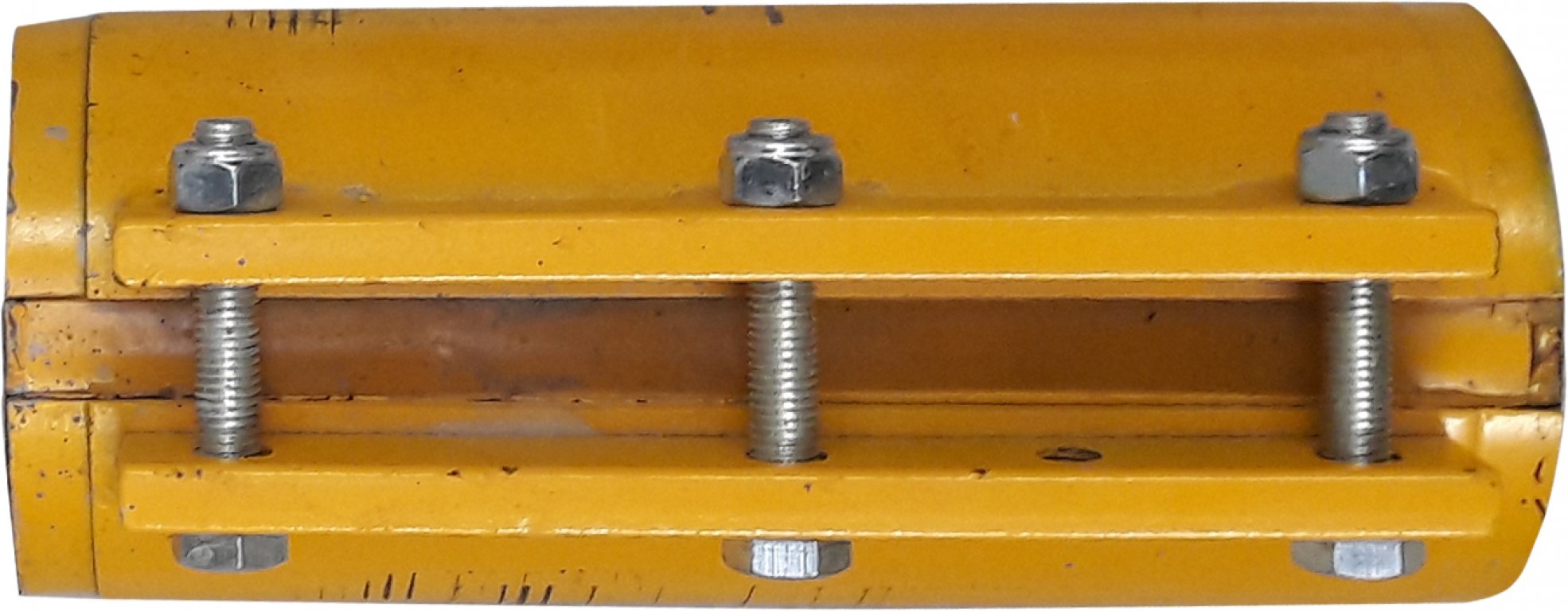

Set “Ü2”-Cabrio (Rotor/stator 2R6)

- Ø 101 mm, 100 l/min, 30 bar - for e.g. floor levelling compound

Scope of delivery:

Suction flange, pressure flange, mortar pressure gauge, pump shaft with Rotex coupling, rotor/stator 2R6, coupling M part 50 (2” IT), 2 x eyebolts, 4 x M16 nuts, 2 x M16 threaded rods (270 mm), 2 x M16 double nuts

Set “Ü”-Cabrio (Rotor/stator 1R6)

- Ø = 101 mm, 100 l/min, 15 bar, e.g., for floor levelling compound

Scope of delivery:

Suction flange, pressure flange, mortar pressure gauge, pump shaft with Rotex coupling, rotor/stator 1R6, coupling M part 50 (2” IT), 4 x M16 nuts, 2 x M16 threaded rods (90 mm), 2 x M1 double nuts

Optional drive unit 280 rpm for small silo Cabrio

If the small silo is used exclusively for processing spray applications, e.g., reprofiling mortar, there is the option of selecting the drive unit with 280 rpm for the standard drive unit with 373 rpm.

Set “D”-Cabrio (Rotor/Stator D7-2.5 S)

- Ø 89 mm, 22 l/min, 40 bar, e.g., for spray applications

Scope of delivery:

Metering shaft – gradient 30 mm, suction flange, pressure flange, mortar pressure gauge, pump shaft with Rotex coupling, rotor/stator D7-2.5 S, coupling M part 50

Vibrating unit for one-way-container

The vibrating unit is belted directly onto the one-way container

- For non-flowing powder material in a one-way container

- Prevents tunnel formation in the material hopper

Scope of delivery:

Vibrating unit with support bracket, tension belt and power cable

Double adapter for vibrating unit

- Double adapter 230 V CEE for a vibrating unit on a one-way container

If both one-way containers that supply the Cabrio with material via the inoFLEX Duo are equipped with a vibrating unit, two double adapters are required (one adapter for each rotor sensor / one adapter for each vibrating unit)

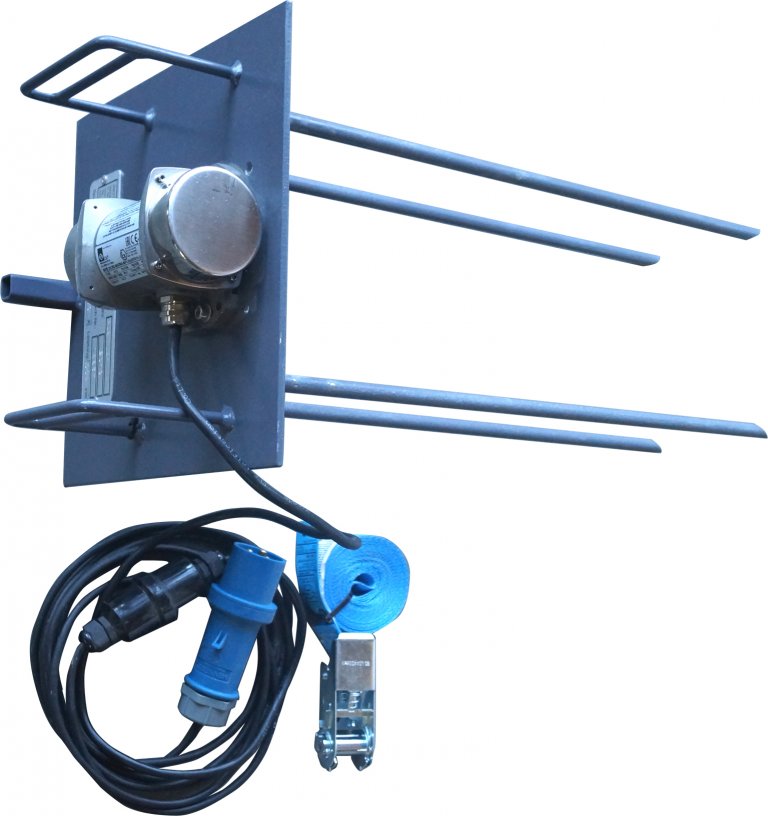

Vibrating unit with vibration rods for OWC and big bags

The vibration unit is stuck directly into an OWC or big bag and secured with a tension belt

- • For non-flowing powder material in an OWC or big bag

- • Prevents ‘tunnel formation’ or ‘bridges’

Scope of delivery:

Vibrating unit assembled on plate with vibration rods, including 230 V connecting cable and tension belt.

For Big bags: Attachment hood for inoCOMB Cabrio for filling with big bag

- without cover for filler hole

Metering shaft - gradient 30 mm for set “D”-Cabrio

Metering shaft - gradient 45 mm for set “Ü1-” and “Ü2”-Cabrio

Metering shaft - gradient 80 mm with double gradient for set “Ü1”- and “Ü2”-Cabrio

Multi-purpose hose

- For universal use, e.g. air, water

- GEKA couplings crimped with sleeves on both sides

| Technical data: | |

| Max. operating pressure: | max. 15 bar |

| Temperature range: | -20 up to +90°C |

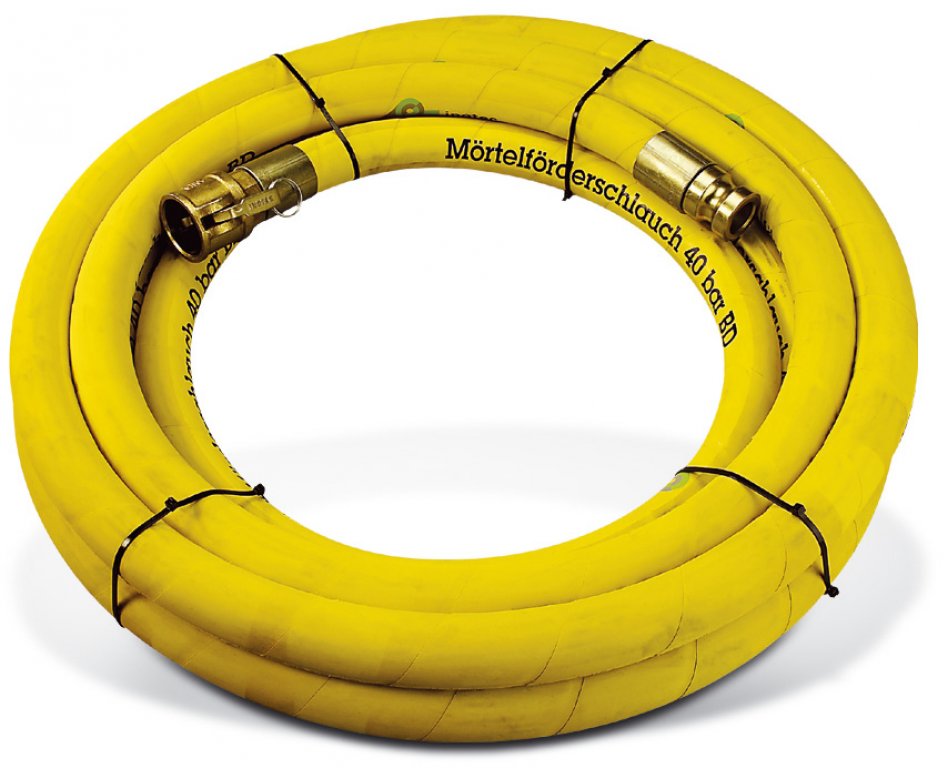

INOTEC mortar hose

- Abrasion-resistant special hose for pumping highly pressurised wet mortar; largely kink-proof

- For an operating pressure of 40 bar with 3 times the reliability

- Yellow on the outside at Ø 35 mm

- Black on the outside at Ø 40 and Ø 50 mm

- With mortar hose couplings, M-piece and rotating V-piece (only with diameters of 25 mm)

- With cam levers on the M-piece

| Technical data: | |

| Operating pressure: | 40 bar |

| Bursting pressure: | 120 bar |

Hose mixer for special strokes

- The material is re-mixed with the hose mixer.

inoFLEX Duo

Two dry delivery units for indirect filling from two Big-Bag-Box Monos or two one-way containers

- The two flexible delivery shafts transport the material to be processed from two one-way containers or two Big-Bag-Box Monos directly into the hopper of the small silo

Scope of delivery:

Covering hood, 2 flexible delivery shafts, 2 motors, 2 rotary blade sensors

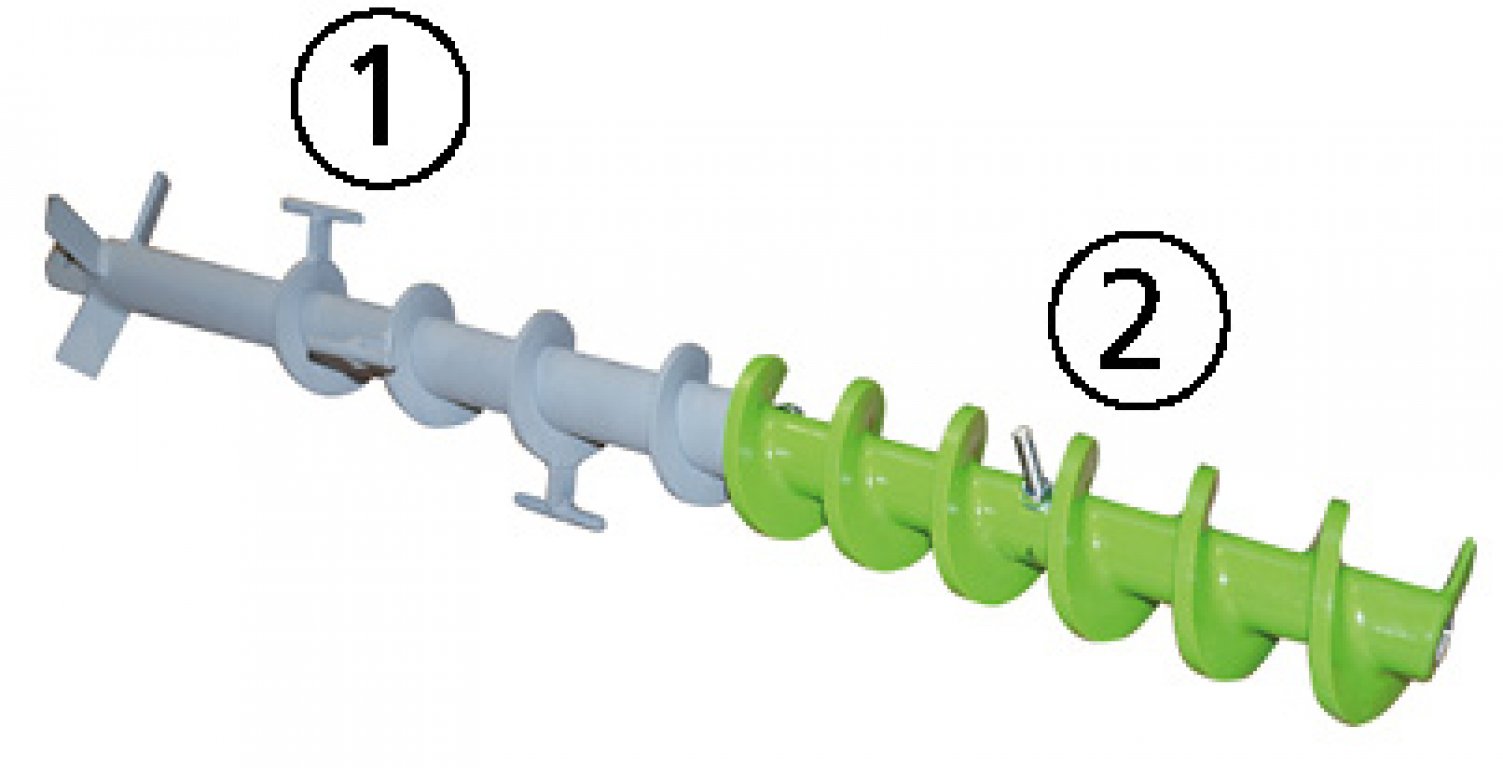

Metering shaft with square mounting

gradient 45 mm with PU insert 330 mm, gradient 55 mm (1 & 2)

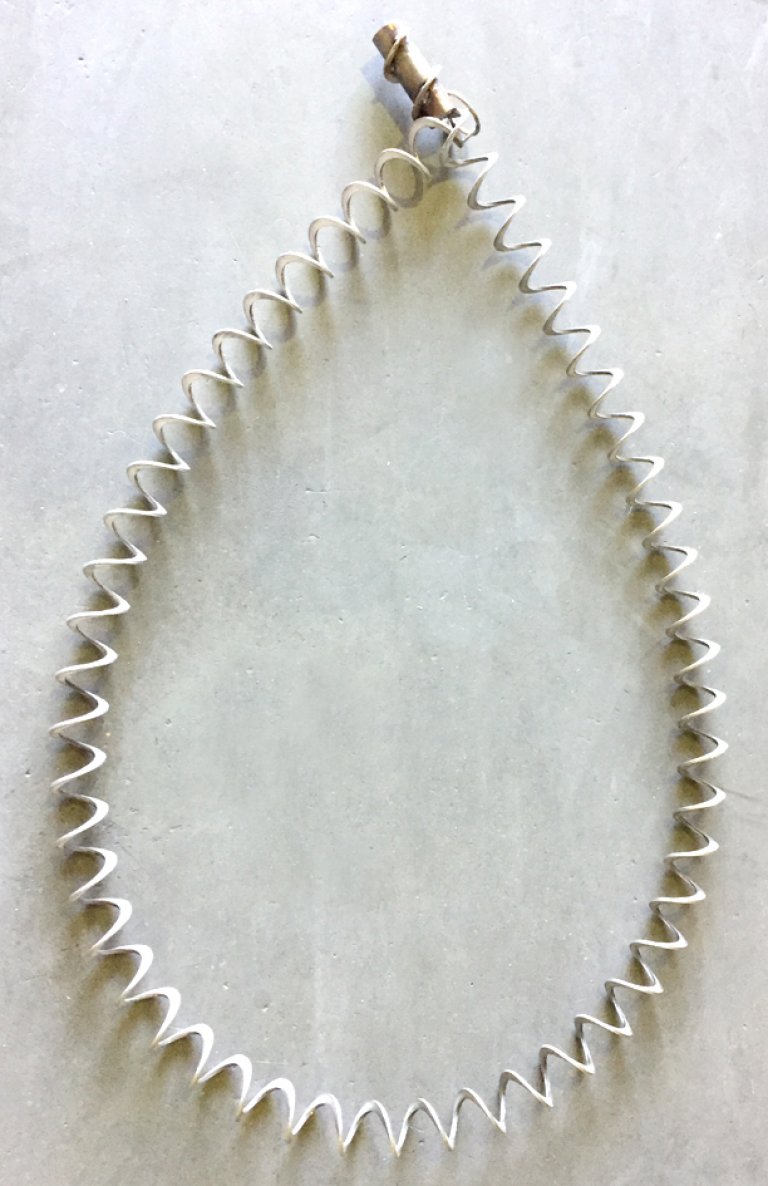

Delivery shaft for the inoFLEX Duo (L=3,200 mm)

Protective hose for delivery shaft inoFLEX Duo

-

L = 1800 mm, incl. couplings, V part 3”, assembled

Three-motor industrial vacuum cleaner inoCLEAN 350

- For very fine dust with automatic filter cleaning

- Very powerful thanks to its three motors

- Low noise levels

- Easy to use

- With HEPA filter H

- For dry use

Technical data:

- Operating voltage: 230 V / 50 Hz

- Motor rating: 3 x 1.2 kW

- Volumetric capacity: 50 l

- Vacuum 230 mbar

- Airflow: 510 m3/h

- Dimensions: 800 x 600 x 1,180 mm

- Weight (without accessories): 65 kg

Scope of delivery: Vacuum cleaner complete with 3 motors & HEPA filter, suction tube, 5 m suction hose ø 50 mm, floor suction nozzle

400 V / 5 x 4 mm² extension cable

- 32 A plug and coupling

230 V / 3 x 2.5 mm² extension cable

- 16 A Schuko plug and coupling

Wireless remote control

- Wireless remote control, 3-channels, with handheld transmitter, integrated antenna, 4-pole Harting plug with LED display

- Only for devices with a control voltage of 24 V / 42 V

- Function: ON / OFF/ TEST

Remote control extension cable without remote control switch

- For remote control cable

- For remote control switch

- For inoCOLL / inoCOLL Pro one-handed gun

Remote control switch

- With 0.2 m cable, indicator light and 4-pin Harting plug

Static mixer

- Prevents / destroys node in mortar

- Diameter: 35 mm

- Length:200 mm

- incl. Coupling M-piece 35 mm and V-piece 35 mm

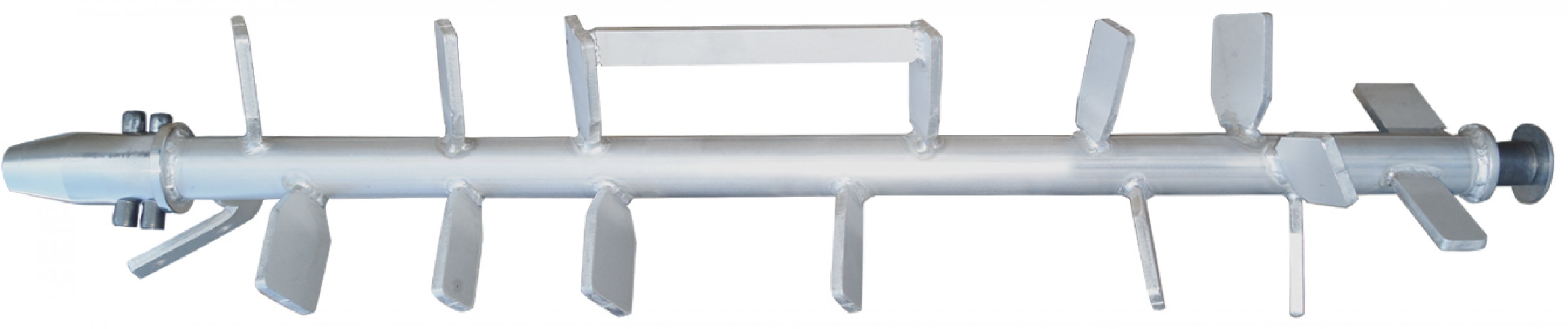

inoPOWERMIX+ “S” PU mixing pipe, complete, with wide material discharge for stiff material with high delivery rate

including PU inlay, steel frame with eccentric fastenings, mixing pipe cover and mixing shaft (stainless steel) (e.g. drainage mortar, industrial screeds, etc.)

Reprofiling sprayer

- Reprofiling sprayer 35 V with nozzle pipe 12 mm, connection 35 V-piece

Coupling reducer

- For connecting two mortar hoses or reducing the machine outlet.

Plaster piece for cleaning mortar hoses

Sponge balls

- For cleaning material / mortar hoses

PQm65 booster pump with GEKA coupling for raising the water network

(Observe local regulations)

- 230 V / 50 Hz / 0,55 KW, 6 bar

- Including connecting cable

Check valve set including GEKA coupling and 1 metre hose

Water barrel for inoCOMB Cabrio

- incl. 2 m water hose between the water barrel and the booster pump with GEKA coupling

- incl. PQm65 booster pump (Art.-Nr. 10044111)

- incl. Check valve set (Item no. 10006508) with 2 m hose

PU mixing tube inoPOWERMIX short with wide material outlet for inoMIX S50 / F52 (stainless steel mixing shaft)

- including PU inlay, steel frame with eccentric locks, mixing tube cover and stainless steel mixing shaft

Stainless steel mixing shaft for inoPOWERMIX short for inoMIX S50 / F52

- (e.g. floor levelling compounds, bricklaying mortar, drainage mortar, industrial screeds, etc.)