Floor sander BS-270-EL-9 |  Floor sander BS-520-EL |  Shot blaster system S210E40R Streamer |  Shot blaster system S270E75R Streamer | |

| Blasting EP and PU coatings | ||||

| EP and PU coatings: Removal of old coatings, roughening of new coatings, roughening of concrete or screed | ||||

| Industrial flooring: Restoration and remedy | ||||

| Keying and removal of mineral substrates | ||||

| Natural and artificial stone, terrazzo: grinding of slabs made of artificial stone, hard and soft stone up to polishing, grinding and honing of terrazzo | ||||

| Remedy of surface roughness | ||||

| Removal of sanding bridges and blast tracks | ||||

| Removal of sealants and thin coatings | ||||

| Screed: Grinding and polishing, tackling irregularities | ||||

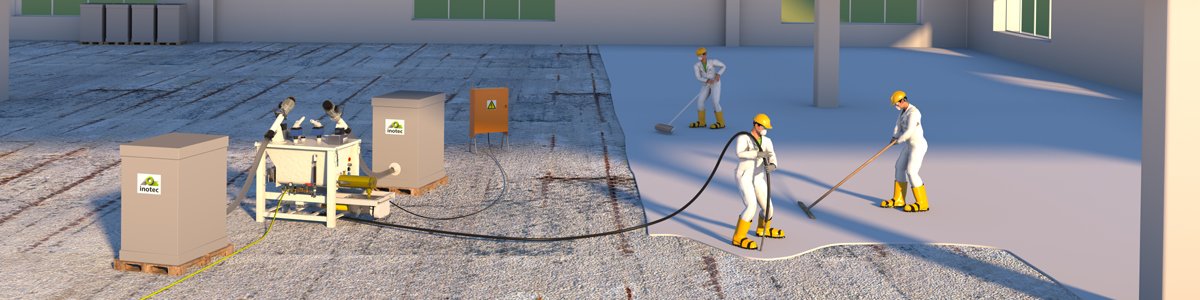

| Shot-blasting of concrete, screed and asphalt to remove cement slurry and for substrate preparation | ||||

| Shot-blasting of steel to remove sinter layers and for rust removal | ||||

| Topsoil transfer: substrate preparation, removal of spattling compounds and adhesive residues |

Floor sander BS-270-EL-9 |  Floor sander BS-520-EL |  Shot blaster system S210E40R Streamer |  Shot blaster system S270E75R Streamer | ||

| Operating voltage | V/Hz/A | 230 / 50 / 16 | 400 / 50 / - | 400 / 50 / 32 | 400 / 50 / 32 |

| Drive performance | kW | 2,2 | 3,0 | 4,0 | 7,5 |

| Rotational frequency | r/min | 1.430 | 900 | ||

| Machine technique | Floor processing | Floor processing | Floor processing | Floor processing | |

| Working width | mm | 270 | 520 | 210 | |

| Working pressure | kg/cm² | 25 | 90 | ||

| Dust extraction connection | mm | 38 | 51 | ||

| Comments | Required tools: 4 pcs. | * Rotations continuously variable | * Rotations continuously variable | ||

| Dimensions (L x W x H) | mm | 860 x 470 x 1 | 980 x 580 x 1080 | 1100 x 300 x 1000 | 1250 x 390 x 1050 |

| Weight | kg | approx. 57 | approx. 130 | approx. 114 | approx. 166 |

| Beam power on concrete | m²/h | 80 | 130 | ||

| Filter connection | mm | Ø 50 | Ø 75 | ||

| Rotations | min-1 | 0 - 18 * | 0 - 30 * |