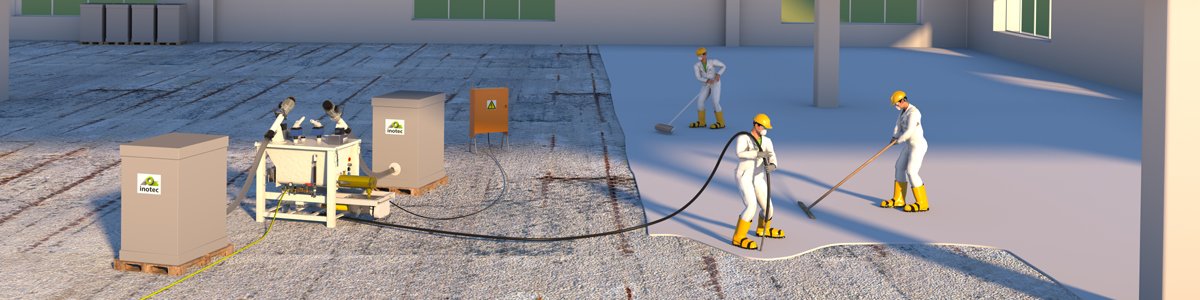

Universal grinding machine with two grinding wheels in opposite directions

Benefits at a glance

- Low weight

- Uneven running thanks to tool disks running in opposite directions

- Level evenness thanks to a large working surface

- Wide application area because of comprehensive accessories

- Separating the tool and the drive

- Continuous speed regulation makes it possible to adapt to the particular craft

- High delivery rate

- Compatible with rucksack vacuum, therefore great flexibility of movement

The inoPLAN Universal grinder is an all-rounder and is therefore light and convenient to use. The motor is easy to mount on the belt and power is transmitted via a flexible shaft. The hand piece of the versatile grinding machine is especially light, with two grinding disks which rotate in opposite directions. This ensures a smooth operation, while offering a large contact and grinding surface for even surfaces. Together with the optional backpack vacuum and comprehensive accessories, the inoPLAN Universal is able to master virtually any grinding job effortlessly.

Service details

| Operating voltage | V/Hz/A | 230 / 50 / 16 |

| Drive performance | kW | 0,9 |

| Grinding wheels (Ø) | mm | 200 |

| Rotational frequency | r/min | 120 - 600 |

| Machine technique | Special grinders | |

| Comments | No warranty claim when grinding without extraction! * Weight motor additionally: 2,5 kg | |

| Weight | kg | approx. 2,4 * |

Scope of delivery

inoPLAN Universal

Item no. 10019283

- With dust suction hood

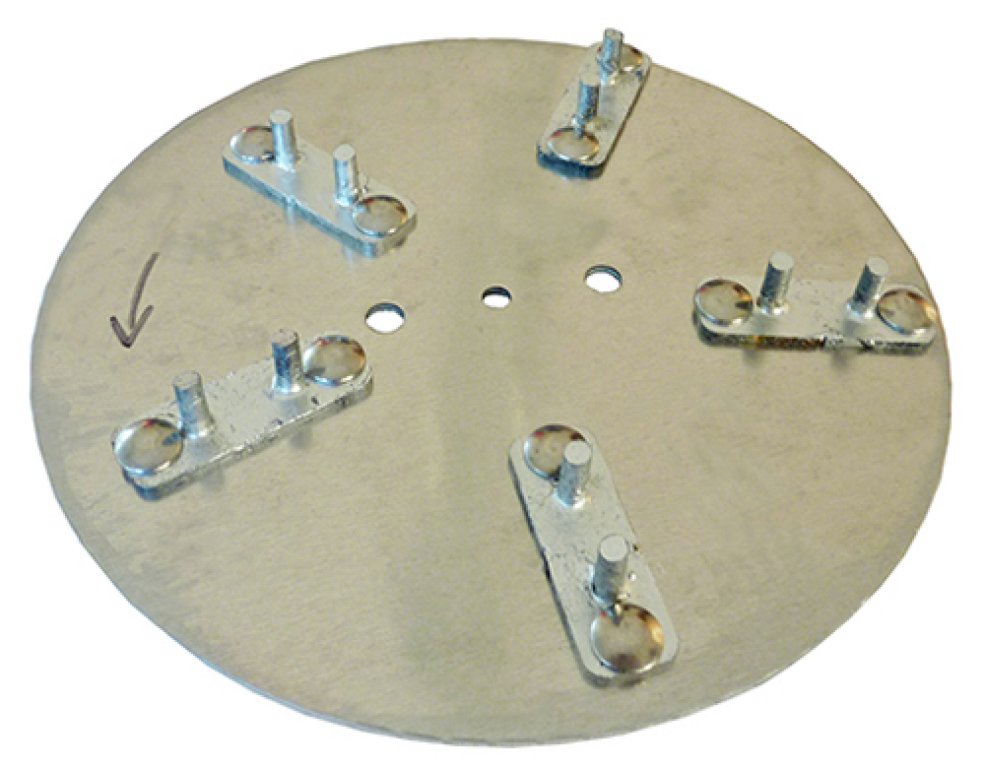

- 1 pair of velour-backed support plates, diameter 200 mm

- Plastic carry case

- Operating instructions

- Backpack vacuum (optional)

Smoothing plates / Application: Smoothing (pair, 200 mm diameter each)

- Concrete surfaces can be smoothed quickly and easily using the plastic smoothing discs. When it comes to surface treatment, it is important that the concrete floor has not yet completely set (sprayed concrete).

Smoothing discs with steel blades / Application: Smoothing (pair, 200 mm diameter each)

- For smoothing concrete and other surfaces (moist concrete, inside of silos)

Support plate with Velcro / Application: Grinding (pair, 200 mm diameter each)

- For attaching sanding disks, abrasive mesh, metal abrasive discs and cleaning pads

Emery* / Application: Grinding, cleaning, roughing

- Surface grinding: Polystyrene insulation panels, rockwool strips and other full thermal insulation systems, panel joints, plaster rendering base

- Cleaning formwork (for an absorbent lining), etc.

- Roughing polystyrene surfaces

----------------------------------

* for use with support plate (Item no. 10019355)

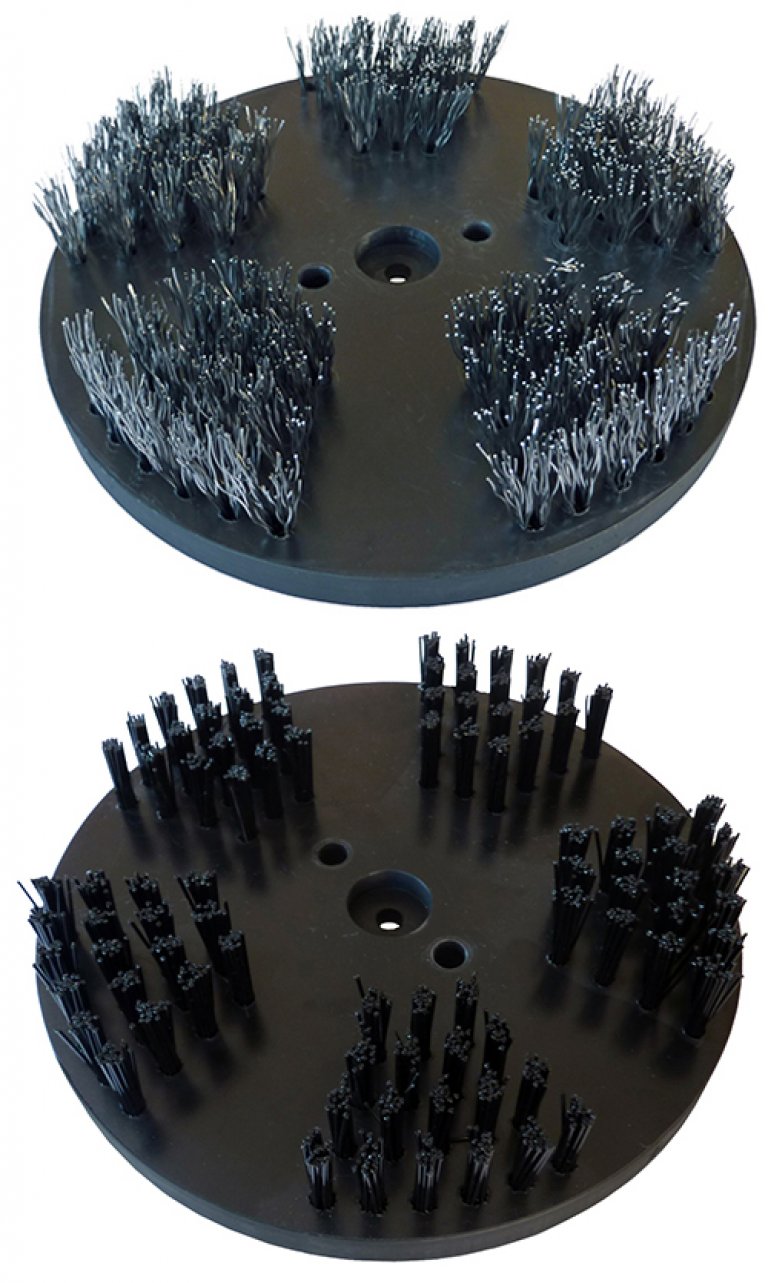

Steel- and Nylon brushes / Application: Cleaning (pair, 200 mm diameter each)

- Cleaning of shell elements, removal of loose plaster and paint

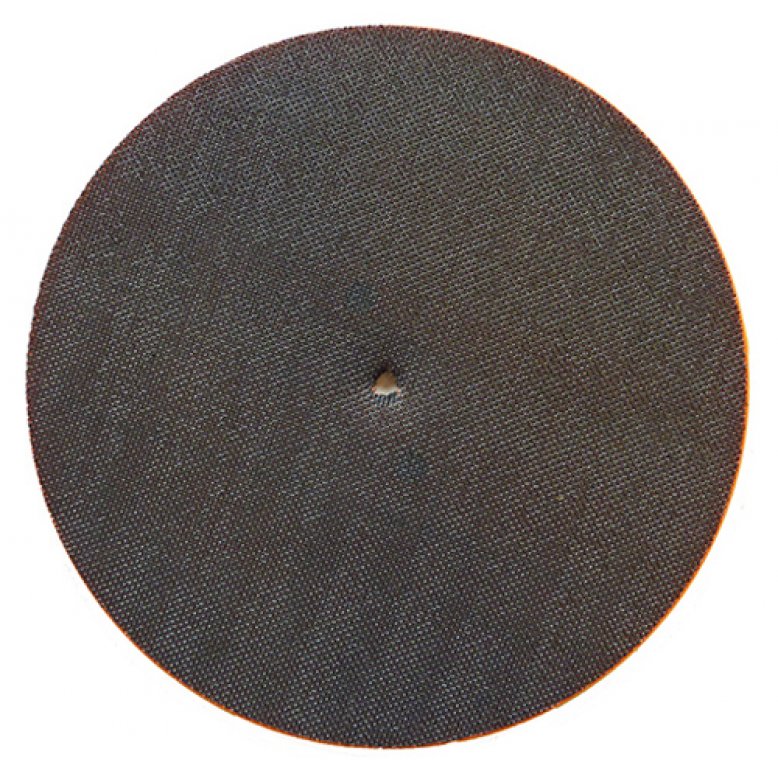

Grinding fleece* / Application: Cleaning and polishing (pair, 200 mm diameter each)

- For cleaning formwork and visible concrete, building and facade cleaning, polishing e.g. of marble effect and wood

---------------------------------------------

* for use with support plate (Item no. 10019355)

“Long life” abrasive disc / Application: Scratches (pair, 200 mm diameter each)

- Abrasive discs with pointed tips are used for doctoring sgraffito. The large contact surfaces guarantee safe and even work with abrasive discs.

- Fibre-glass wallcoverings can also be opened with abrasive discs.

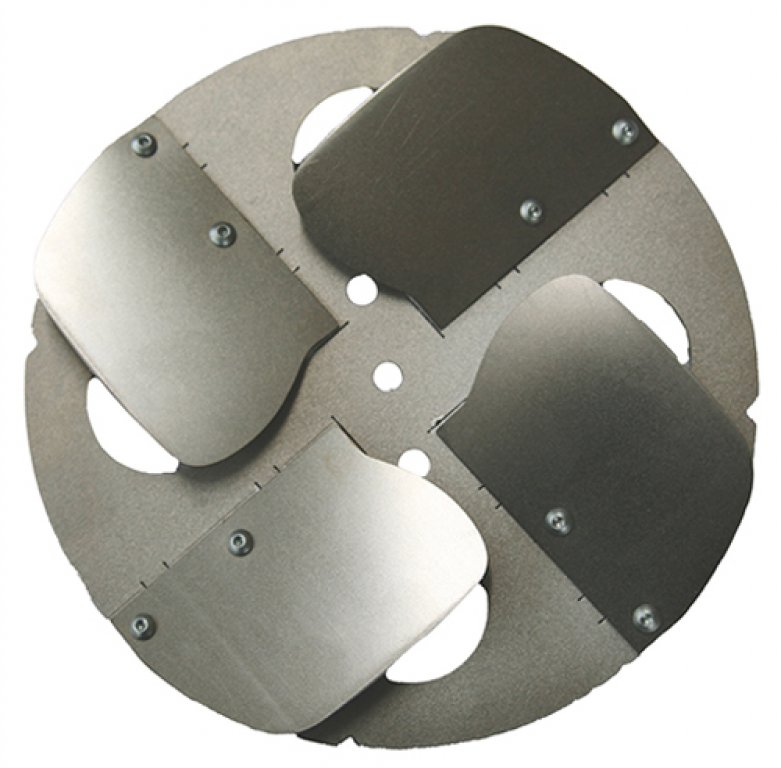

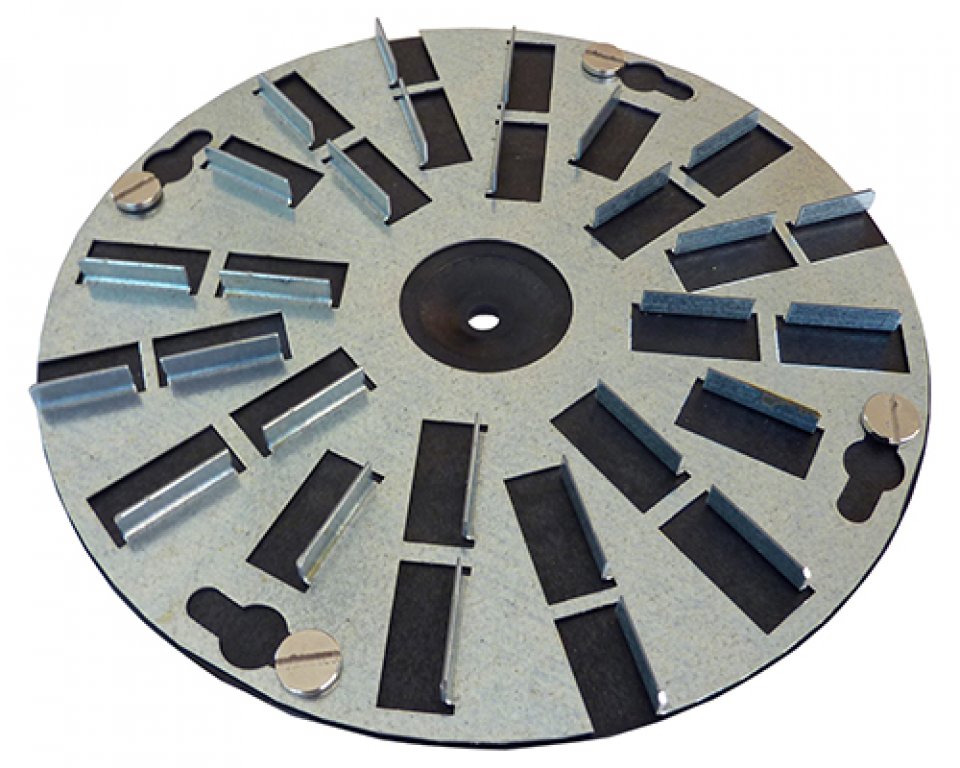

Widia discs / Application: Removing old plaster (pair, 200 mm diameter each)

- For removing sandy old plaster and for roughing dry plaster.

- For milling away carpet and tile mortar adhesive and removing significant soiling from industrial floors.

- Work rate for tile mortar: approximately 20 - 30 square metres per hour

Rubbing board attachment (for use with base plate) / Application: Rubbing (pair, 200 mm diameter each)

• Rubbing board attachments with blunt cutting surfaces are used for rubbing base plaster, gypsum and insulating plaster after they have been hardened.

Backpack vacuum for complete freedom of movement

- Large filter bags (15 l content), short hose distance, therefore considerable suction performance, no electronics susceptible to breakdown, sturdy and high-performance processing, additional socket in the device

Technische Daten

| Motor rating | 1.100 W |

| Weight | 6.5 kg |

| Flow volume max. | max. 60 l/s |

| Vacuum max. | 190 mbar |

| Hopper volume | 15 l |

| Dimensions | 20 x 43 x 63 cm (L x W x H) |

Paper filter bags, 15 l content

- For fine dust, .e.g. gypsum, rock wool dust and normal building dust.

Material filter bag with zip fastener for emptying, 15 l content

- Only for polystyrene dust.