The S210E40R Streamer is the “espresso” of shot blasters

Benefits at a glance

- Powerful impeller motor

- Height-adjustable steering arm, with integrated control elements.

- Multi-adjustable feed thanks to powerful three-phase drive

- Extremely good handling

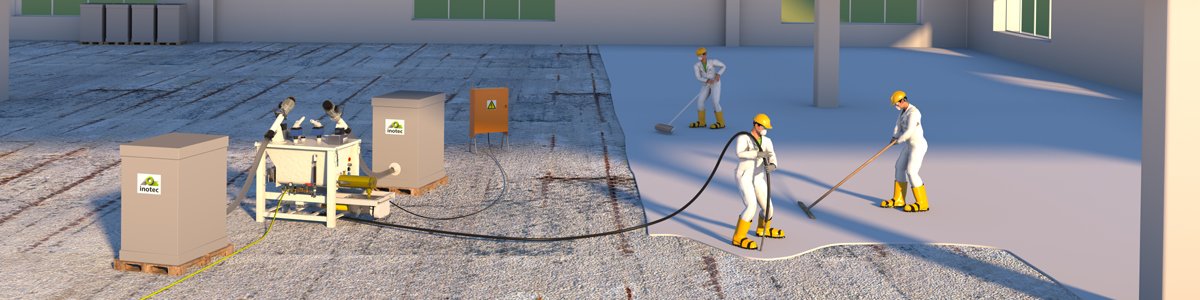

The compact and robust design of the S210E40R Streamer, as well as its easy handling, make it easy to use even in hard-to-reach areas.

The powerful three-phase drive allows a multi-adjustable feed. Main areas of application include corridors, garages, terraces, cellars, landings, loading ramps, etc.

To generate the optimum blast output, we recommend using the S210E40R Streamer along with one of the filter systems in the series DUSTCOM 3003AR.

| Operating voltage | V/Hz/A | 400 / 50 / 32 |

| Drive performance | kW | 4,0 |

| Machine technique | Floor processing | |

| Working width | mm | 210 |

| Beam power on concrete | m²/h | 80 |

| Filter connection | mm | Ø 50 |

| Rotations | min-1 | 0 - 18 * |

| Comments | * Rotations continuously variable | |

| Dimensions (L x W x H) | mm | 1100 x 300 x 1000 |

| Weight | kg | approx. 114 |

Shot blaster system S210E40R Streamer | |

| Blasting EP and PU coatings | |

| EP and PU coatings: Removal of old coatings, roughening of new coatings, roughening of concrete or screed | |

| Industrial flooring: Restoration and remedy | |

| Keying and removal of mineral substrates | |

| Natural and artificial stone, terrazzo: grinding of slabs made of artificial stone, hard and soft stone up to polishing, grinding and honing of terrazzo | |

| Remedy of surface roughness | |

| Removal of sanding bridges and blast tracks | |

| Removal of sealants and thin coatings | |

| Screed: Grinding and polishing, tackling irregularities | |

| Shot-blasting of concrete, screed and asphalt to remove cement slurry and for substrate preparation | |

| Shot-blasting of steel to remove sinter layers and for rust removal | |

| Topsoil transfer: substrate preparation, removal of spattling compounds and adhesive residues |

Scope of delivery

Streamer S210E40R Set

Item no. 10030022

- STREAMER S210E40R shot blaster

- Abrasive S330, 300 kg

- Filter system DC 3003AR, incl. filter cartridges

- Dust hose Ø 70 mm, 10 m

- Magnetic brush 500 mm

- Maintenance box

- Operating instructions