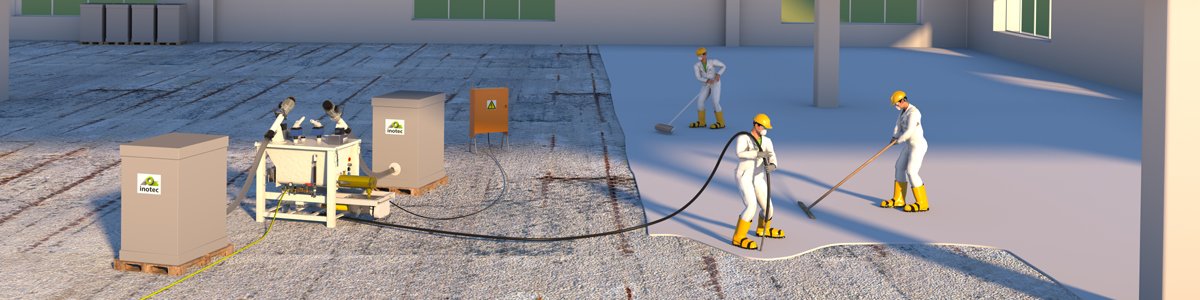

The perfect silo continuous mixer for processing powdery materials

Benefits at a glance

- Constant material consistency

- High mixing rate

- PU mixing pipe with quick-release fasteners

- Standard flange attachment with a diameter of 250 mm and thus suitable for all conventional silos

- Automatic rotation direction detection

- Very simple operation and cleaning

- Low-maintenance and construction site compliant technology

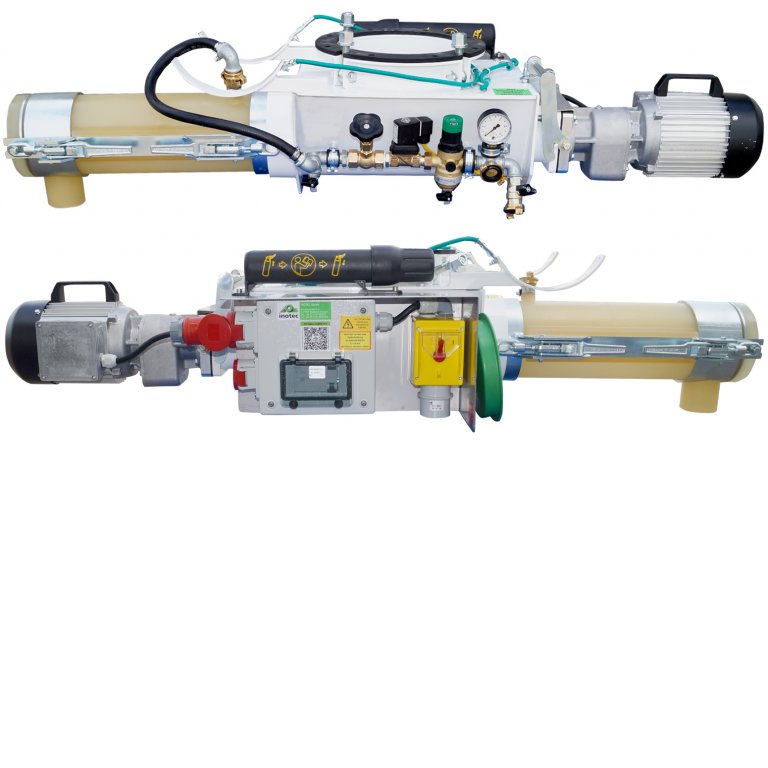

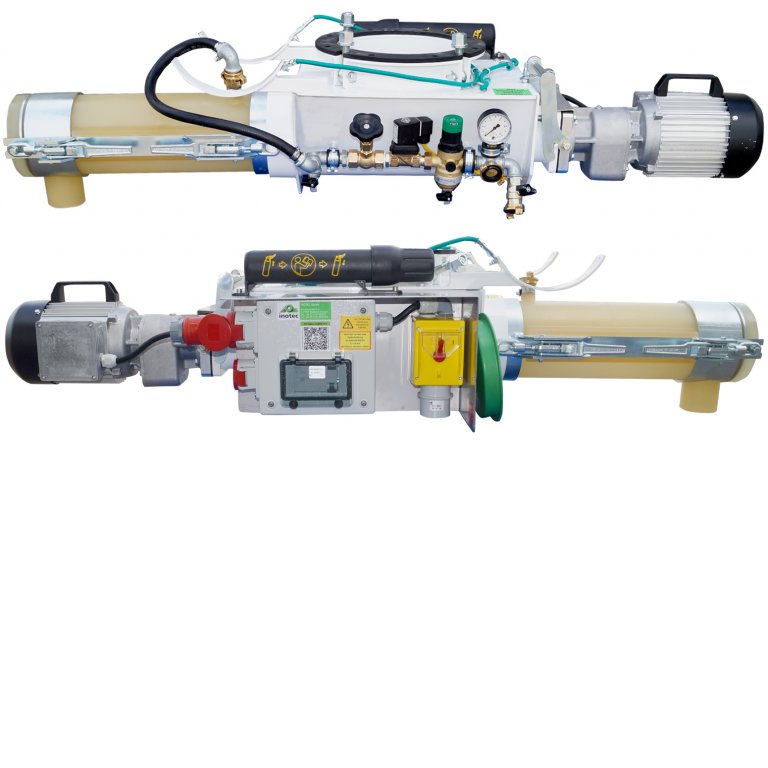

The inoMIX F51 is the perfect 400 V continuous mixer for use with silos for mixing powdery materials.

Its compact design means that the inoMIX F51 can also remain flange-mounted to the silo during transport.

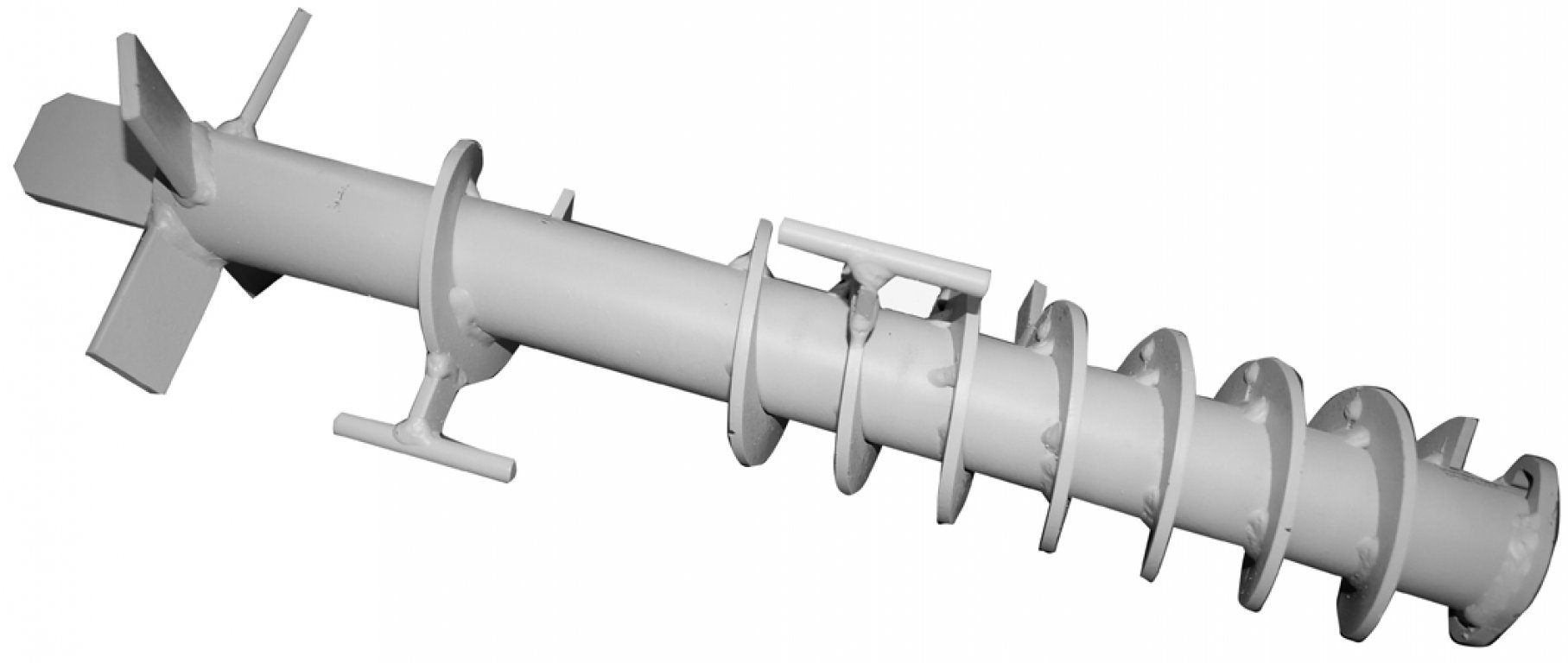

The mixing and metering shafts are driven directly using a gear motor.

This video shows the assembly and operation of the inoMIX F51 continuous flow mixer.

It does not replace reading the original operating instructions.

Video

Alternative Machines

Service details

| Operating voltage | V/Hz/A | 400 / 50 / 16 |

| Drive performance | kW | 2,6 |

| Mixing performance | l/min | max. 22 l/min - ca. 50 l/min* |

| Machine technique | Mixers | |

| Comments | * with steel metering shaft (pitch 40 mm) | |

| Dimensions (L x W x H) | mm | 1500 x 500 x 320 |

| Weight | kg | approx. 65 |

inoMIX F51 | |

| Cement pastes, suspensions | |

| Cement plasters | |

| Dried clay plasters | |

| ETICS glue, mineral | |

| Fire protection mortar | |

| Floating screeds | |

| Floor spattling compounds | |

| Grout | |

| Grouting mortar | |

| Gypsum filling compounds | |

| Light masonry mortar | |

| Lime cement plasters | |

| Lime plasters | |

| Lime smoothers | |

| Loam plasters | |

| Masonry mortar | |

| Mineral textured plasters | |

| Multi-layer acoustic spray plasters | |

| PCC- and SPCC-mortar / filler | |

| Rear masonry mortar | |

| Renovating plaster systems | |

| SPCC Spatula | |

| Trass drainage mortar |

Scope of delivery

inoMIX F51:

Item No. 10043789

- Solid steel funnel

- inoPOWERMIX “S” mixing pipe, complete

- Mixing shaft

- Metering shaft

- Gear motor

- Water fitting

- Operating instructions

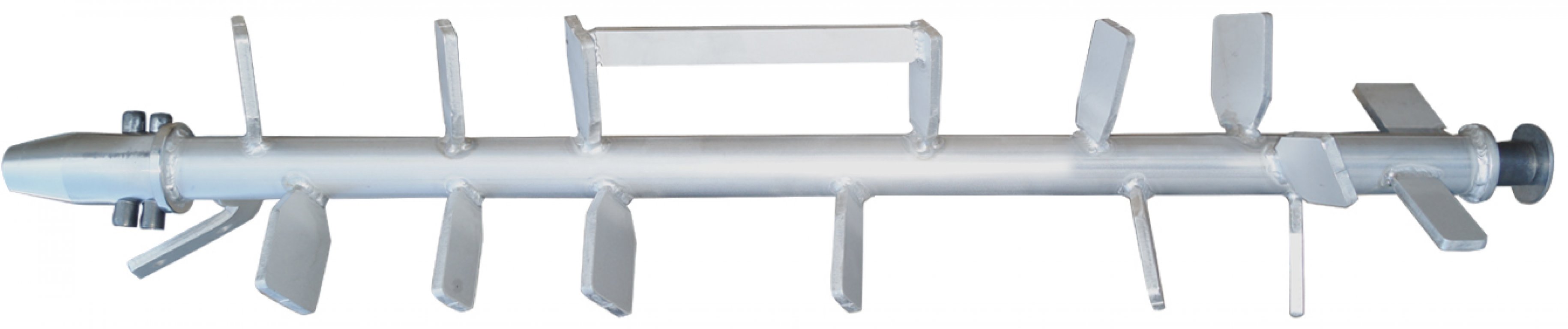

inoPOWERMIX “S” mixing pipe, complete (inoMIX F51)

including PU inlay, steel frame with eccentric fastenings, mixing pipe cover and mixing shaft (stainless steel) (e.g. floor levelling compounds, masonry mortar, etc.)

Mixing shaft for inoPOWERMIX “S” (stainless steel)

(e.g. floor levelling compounds, masonry mortar, drainage mortar, industrial screeds, etc.)

Electric vibration motor (three-phase unbalance motor) as external vibrator for attachment to silos to prevent material flow or compression problems.

- Mains voltage: 400 volts / 50 Hz, 5 m connecting cable

Multi-purpose hose

- For universal use, e.g. air, water

- GEKA couplings crimped with sleeves on both sides

| Technical data: | |

| Max. operating pressure: | max. 15 bar |

| Temperature range: | -20 up to +90°C |

400 V extension cable, 5 x 2.5 mm², length 20 m

- 16 A, CEE plug and coupling

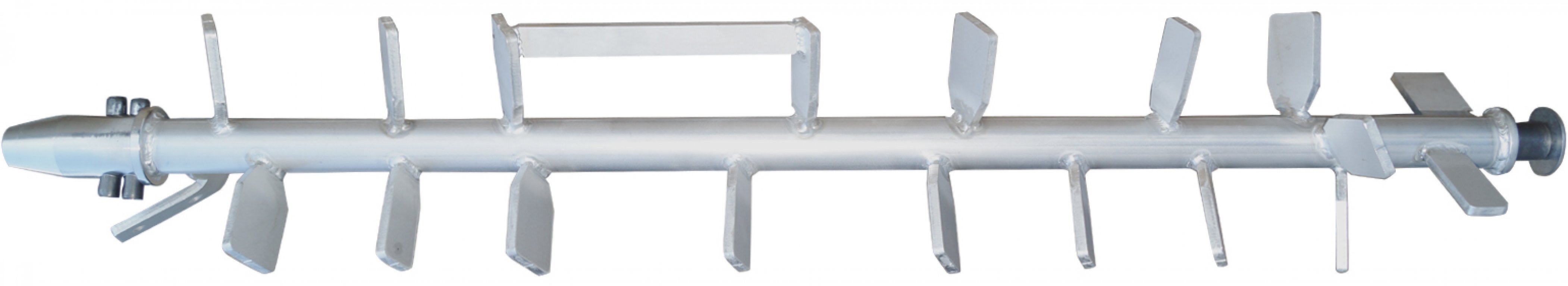

inoPOWERMIX+ “S” PU mixing pipe, complete, with wide material discharge for stiff material with high delivery rate

including PU inlay, steel frame with eccentric fastenings, mixing pipe cover and mixing shaft (stainless steel) (e.g. drainage mortar, industrial screeds, etc.)

inoPOWERMIX “L” mixing pipe

including PU inlay, steel frame with eccentric fastenings, mixing pipe cover and mixing shaft (stainless steel)